Difference between Precision Wirewound and Foil Resistors

Introduction

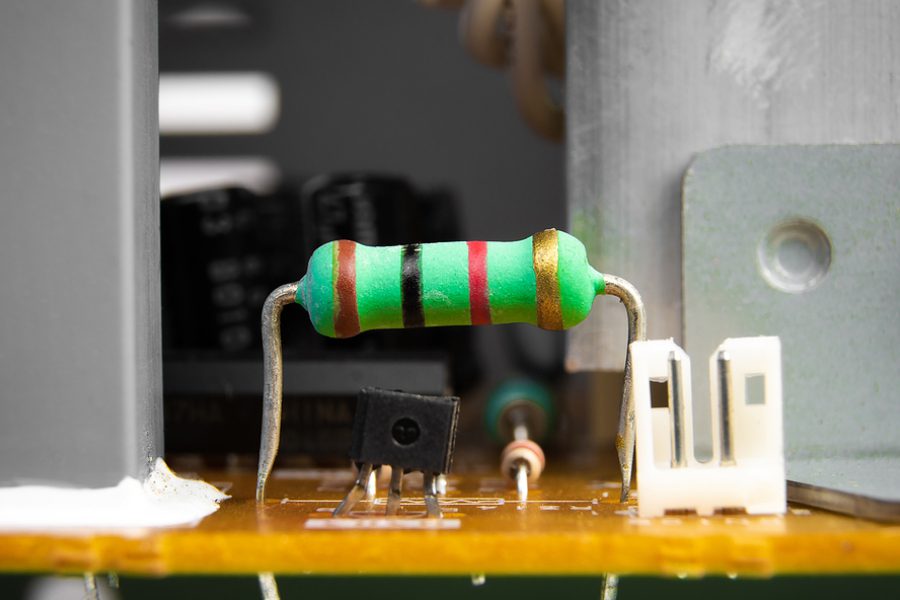

Precision wirewound resistors are used in a wide range of applications. They are used as voltage dividers, current sense resistors, timing circuits etc. In high power supplies, precision wirewounds are commonly used for voltage regulation. Foil type resistors have many advantages over the precision wirewound types but there are some applications where their performance is not good enough to be chosen as a component in circuit design.

The resistance value of precision wirewound is generally higher than foil type resistors

The resistance value of precision wirewound is generally 30% higher than Foil type resistors. This means that the precision wirewound resistor can handle more current and heat, which makes it a better choice for applications where power dissipation is an issue.

Precision wirewound resistors are used for high frequency applications

Precision wirewound resistors are used for high frequency applications. They are typically made of thin wires wound around a ceramic core that is enclosed in an insulating material such as porcelain or glass.

Foil resistors, on the other hand, can be manufactured using either metal foil or wire. The resistor is then encased in an insulating material such as epoxy resin or plastic casing with leads attached to it so they can be connected to other components on printed circuit boards (PCBs).

Foil type resistors use a small amount of metal foil as an electrical conductor, which is wound up into a form resembling a coil

Foil type resistors use a small amount of metal foil as an electrical conductor, which is wrapped around with a layer of insulation material and wound up into a form resembling a coil. Foil resistors can be made from high temperature tolerant materials such as aluminum oxide or silicon carbide (SiC). Foil resistors are used for high frequency applications where the resistance value changes with temperature variation.

They are more expensive than wirewound resistors because they require more precise manufacturing techniques and therefore cost more to produce.

Precision wirewound resistors are better than foil types when it comes to performance in terms of stability and consistency

Precision wirewound resistors are better than foil types when it comes to performance in terms of stability and consistency. In precision wirewounds, the resistance value is uniform and constant throughout the entire resistor body. This makes them ideal for high frequency applications such as amplifiers or oscillators, where accurate values are crucial.

Foil resistors, on the other hand, have a non-uniform resistance profile due to their construction method: they’re made by depositing thin sheets of metal onto an insulator material such as mica or ceramic bobbins (hence “foil”). These materials aren’t as good at resisting temperature changes compared with ceramics like mica or alumina–which means that foil resistors can change their value over time due to thermal expansion/contraction effects caused by heating up during operation (or cooling down when not being used).

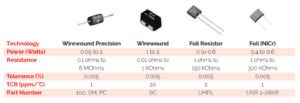

A quick comparison of our high precision (0.005%) offerings:

Check out more options from Riedon here: https://riedon.com/resistors/precision

Contact us to find out more.