What is a Reed Relay & Reed Switch?

Introduction

In this article, we will talk about reed relays and reed switches. We’ll go over their essential components and how they work in order to help you better understand how these devices operate. We’ll also look at some of the applications where these relays are used.

What is a Reed Relay?

A Reed Relay is a electromagnetic switching device that uses a magnet and a spring-loaded reed switch to make contact. Reed Relays are made by placing a coil around one or more reed switches. The relay assembly is then over-moulded, or epoxy sealed into a housing for added durability and handling.

There are also reed relays with mercury inside them and these reed relays are often known as mercury relays.

What is a Reed Switch?

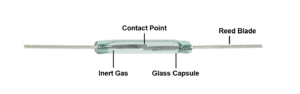

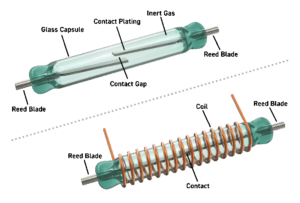

A Reed Switch is a type of switch that uses a magnetic field to detect the presence of an object. The switch itself consists of two ferromagnetic contacts – usually made from nickel or iron – glass envelope that serves to both hold the metal blades in place and to provide a hermetic seal that prevents any contaminants from entering the critical contact areas inside the glass envelope.

When you place your magnet near one end of this assembly, it creates a magnetic field between your magnet and it attracts both blades toward itself; this compresses them together so they touch and establish contact. When you remove your magnet from proximity with one end, its attraction ceases immediately.

How does a Reed Relay work?

A Reed Relay is a device that uses magnetic fields to control the flow of electricity. It’s similar to a mechanical switch, but instead of using electricity to complete or break an electrical circuit, it uses magnetism. This makes them ideal for use in environments where dust and dirt may affect traditional switches or relays (such as those found in vehicles).

A typical reed relay has three parts: reed switch, coil for creating a magnetic field, an optional diode for handling back EMF from the coil.

When current flows through the coil, this creates enough electromagnetic force between the reed blades so that they attract each other – pulling together until they touch one another at their ends. With enough field applied, the blades make contact and electrical contact is made. When current stops flowing through the coil, they will repel each other.

Source: Pickering Relay

What are the applications of a Reed Relay?

Reed relays used extensively throughout test and measurement, medical, alternative energy, and hybrid and electric mobility markets. That is because reed relays offer perfect isolation between the control and load circuits. Also meeting the requirements of reliability, accuracy, speed, and safety. Other common uses include high cycle count, high voltage, low voltage, low current, or RF switching.

The following is a list of some common uses:

- Automotive applications, such as automatic door locks and window controls.

- Industrial control, such as machine tool shutoffs or conveyor systems.

- Telecommunications (e.g., fax machines).

- Home appliances (e.g., microwave ovens), which may contain one or more reed switches to sense when food has been cooked and is ready to be eaten.

- Medical – surgical generators, automated external defibrillators, isolation functions.

Advantages of Reed Relays and Reed Switches

Reed Relays and Reed Switches are compact, reliable and easy to use.

Reed Relays have several advantages over solid state relays:

- They have no moving parts so there is no wear or friction to cause problems over time.

- The contacts are sealed in hermetic glass to prevent contamination and corrosion unlike a typical relay contact would do if it were exposed to air for long periods of time (like when used in an outdoor application).

- Due to their lack of moving parts, reed relays will last much longer than conventional electromechanical relays which often fail after only a few years under heavy loads or harsh environments due to wear from contact points rubbing against one another causing them not work properly anymore due to excessive friction between these surfaces.

Conclusion

Reed relays are extremely reliable and durable due to their simple design: there’s no moving parts or batteries required. They are an excellent alternative to conventional relays because of their durability and extended life expectancy. So, when meticulously designed, the reed relay lives up to the high demands of emerging electronics.

Wiselink offers reed relays in many package styles, some of the types include:

-

High voltage reed relay

-

Mercury wetted reed relay

- SMD reed relay

-

Miniature reed relay

They are namely from:

- Coto Relays https://wiselink.com.sg/manufacturer/coto-technology/

- Pickering Relays https://wiselink.com.sg/manufacturer/pickering-electronics/

Contact us to get started.