Mill-Max New Single and Double Row Omniball® Connectors

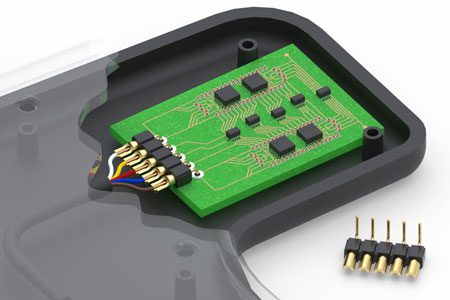

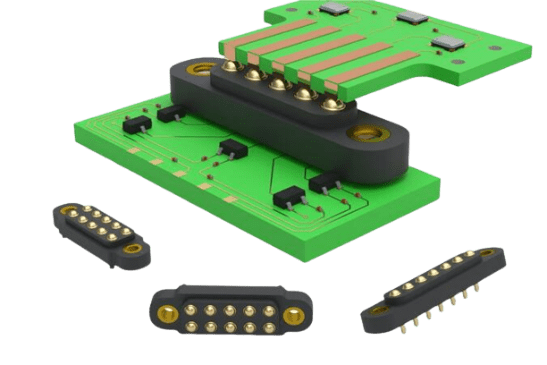

Mill-Max has released their new Omniball® spring-loaded connectors which are offered in single and double-row configurations. These connectors feature a rolling ball interface which is designed to maximise connections between components that slide or revolve into contact.

The connectors use Omniball® contacts and spring-loaded pins in which the traditional plunger has been replaced by a gold-plated, brass ball. When engaged, the ball compresses and rolls, which allows the mating surfaces to make contact and can then easily slide parallel to each other, while spring force ensures consistent electrical contact is regulated. The rolling action helps to avoid binding, premature wearing, and structural failure that traditional, plunger style, spring pin connectors can be prone to in these types of applications.

These connectors have:

- Pin to pin spacing of 4 mm (.1575”)

- 76 mm (.266”) above board height

- Available in through-hole or surface mount termination styles

- Optional threaded inserts that provide secure mounting in rugged applications and for alignment pegs on the SMT connectors

The insulator material is Nylon 4/6 which is known for excellent high temperature performance, dielectric strength, and mechanical toughness. The Omniball® contacts feature .762 mm (.030”) maximum stroke, gold plating on all components, and a 2.3 mm (.091”) diameter ball interface.

The durability of the spring-loaded pins has been tried and tested through 1,000,000 compression cycles and rolled over 108 km (67 miles) at half stroke while still meeting specifications for contact resistance of 30 milliohms, and spring force of 55 grams at mid-stroke (.015”, .381 mm).

Single row connectors are offered in 2-10 positions; part numbers are 845-22-0XX-10-0X1101 (through-hole) and 845-22-0XX-30-XX1101 (SMT). Double row connectors are offered in 4-20 positions; part numbers are 847-22-0XX-10-0X1101 (through-hole) and 847-22-0XX-30-XX1101 (SMT).

The versatility of these connectors provides solutions for innovation interconnect arrangements while optimising electrical, mechanical and structural reliability. It is best suited for applications involving sliding or rotating connections like “twist & lock” cable connectors; docking stations; rack and server drawers, quick connects, and blind mating. They can be mounted in vertical or horizontal orientations and can be used to eradicate cables where circuit board to bus bar connections are made in tight spaces.