Flat and Pointed Tip Spring-Loaded Pins and Connectors

Mill-Max has just announced a new lineup of spring-loaded pins available with either pointed or flat tip plungers. These new pins further expands the extensive offering of spring-loaded products, providing solutions for testing and other specialized connection requirements.

Responding to designers needs for new and varied spring-loaded interconnect solutions, Mill-Max has expanded its spring-loaded product line with new flat tip and pointed tip plunger styles. While the standard full radius plunger tip, found on much of the product line, is an excellent choice for many uses, however, there are applications which require a different solution.

Pointed Tip Plunger

The pointed tip plunger design is often used with spring-loaded pins in test environments. The point design concentrates the force, creating greater pressure to penetrate oxides or other contaminants on the surface of the test unit, thereby providing a high-quality, low resistance connection. Furthermore, another use for pointed tip plungers is for probing or contacting holes or via holes on printed circuit boards. Generally, the point provides a more suitable fit than a radius and can be used in a variety of hole sizes.

Flat Tip Plunger

On the other hand, Flat tip plungers provide greater surface area at the point of connection, distributing the electrical charge and delivering more efficient heat dissipation. An example use would be to reduce the likelihood of arcing in systems that experience power spikes for a short duration, or to decrease the total amount of heat generated in a circuit. Other advantages provided by the flat tip plungers are they allow for greater tolerance misalignment with mating surfaces, and they are a good choice for applications where the spring pin tip makes contact with round component leads.

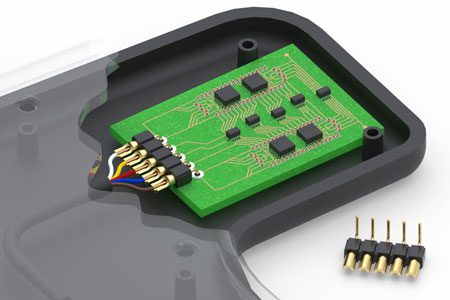

As a whole, both the flat and pointed tip pins are available in surface mount and thru-hole terminations with six unique initial heights and two options for stroke. Furthermore, these pins are made with precision machined components and beryllium copper springs, all gold plated to ensure the highest conductivity, corrosion resistance and durability. They meet all the electrical, mechanical, and environmental specifications of their equivalent full radius style pins.

Complete performance specifications and technical details can be found on Mill Max’s website. Mill-Max also offers these pins in single and double row, .100” (2.54 mm) pitch, connector strips to address a wide range of interconnect applications. See the table below for part numbers and check our website for updates.

|

Part Number |

Plunger Tip Style |

Termination Style |

Single Row Strips |

Double Row Strips |

|

SMT |

811-22-0XX-30-04X101 |

813-22-0XX-30-04X101 |

||

|

Through-hole |

811-22-0XX-10-04X101 |

813-22-0XX-10-04X101 |

||

|

SMT |

811-22-0XX-30-05X101 |

813-22-0XX-30-05X101 |

||

|

Through-hole |

811-22-0XX-10-05X101 |

813-22-0XX-10-05X101 |

Contact us today to request for samples.