Many online electronic component suppliers in Singapore carry two popular options that often come into consideration: pogo pins and traditional connectors. These connectors hold immense significance across diverse applications, such as electronic devices, medical equipment, and automotive applications, as they serve as the backbone for establishing crucial electrical connections.

In this article, we will conduct a comparative analysis of pogo pins and traditional connectors, equipping you with invaluable insights into their shared characteristics, distinguishing features, and key considerations for making an informed choice between the two.

What is a Pogo Pin?

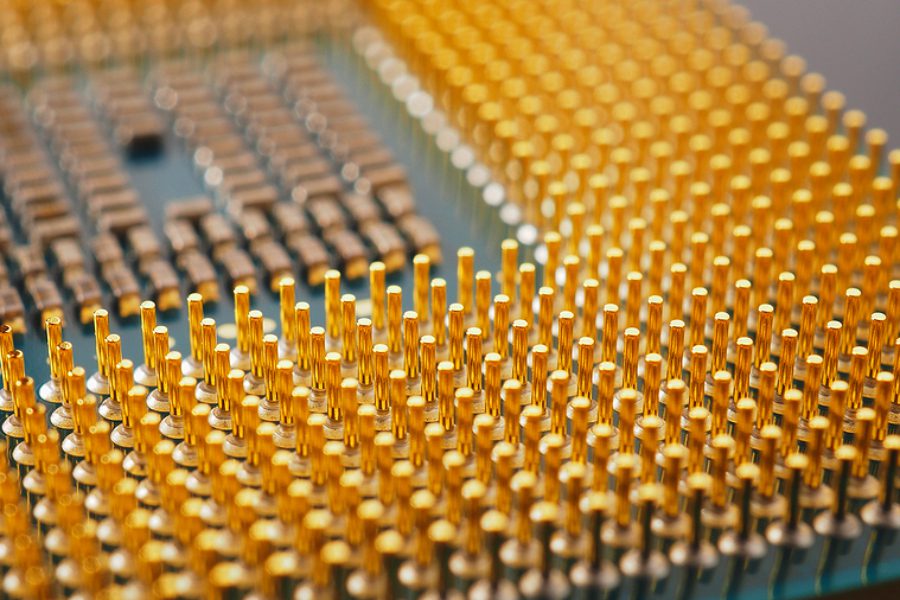

Pogo pins, also referred to as spring-loaded connectors, represent a remarkable advancement in electrical connectivity. These connectors utilise the power of springs to create a temporary connection between two electronic components. Structurally, they comprise a plunger, barrel, and spring, all enclosed within a sturdy metal casing. When compressed, the spring provides the necessary force to establish a secure electrical connection.

What is a Traditional Connector?

Traditional connectors are the more commonly known and recognisable types of connectors. You encounter them in everyday devices, taking forms like USB ports, HDMI connectors, and audio jacks. These connectors rely on a combination of pins, sockets, and protective housings to ensure a robust electrical connection. With a long-standing presence in the industry, traditional connectors have been the trusted choice for countless applications over the years.

Size and Space Considerations

When it comes to size and space constraints, pogo pins have a notable advantage over traditional connectors. Pogo pins are small, compact and can be mounted directly onto a circuit board, saving valuable space in electronic designs. Applications such as wearable devices or miniaturised electronics, where every millimetre counts, greatly benefit from the space-saving attribute of pogo pins. In contrast, traditional connectors often have larger form factors, which might pose challenges in achieving sleek and compact designs.

Durability and Reliability

Durability is a crucial aspect to consider when evaluating connectors. Pogo pins are designed to withstand frequent mating cycles, making them highly durable. Their inherent spring-loaded mechanism ensures a steadfast electrical connection, even when subjected to vibrations or shocks. On the other hand, while traditional connectors are generally dependable, they may experience wear and tear with frequent insertions and removals. Nevertheless, it’s worth noting that high-quality traditional connectors can still deliver commendable durability and reliability, catering to specific needs and requirements.

Electrical Performance

Both pogo pins and traditional connectors offer commendable electrical performance, albeit with some differences. Pogo pins excel in providing low contact resistance and excellent signal integrity due to their design, making them suitable for high-frequency applications. Traditional connectors, depending on their quality and design, may introduce some signal loss or interference. However, it is important to note that high-quality traditional connectors can still deliver reliable electrical performance.

Cost Considerations

Cost is often a significant factor when making connector decisions. Pogo pins, being more specialised and less common than traditional connectors, tend to be more expensive. However, the cost can be justified by their compact size, durability, and performance advantages, especially in applications where space and reliability are paramount. Traditional connectors, due to their widespread use and larger production quantities, are generally more cost-effective.

Conclusion

Choosing between pogo pins and traditional connectors requires careful evaluation of your specific requirements. If you prioritise convenience, space optimisation and durability, pogo pins can be an excellent choice. Conversely, if cost-effectiveness and compatibility with existing systems take precedence, traditional connectors may be the preferred option.

Remember, every application has its unique needs and trade-offs. What works best for one project may not work well for another. By evaluating the factors highlighted in this comparative analysis, you can make a well-informed decision and choose the connector that best meets your individual needs.

Begin your journey with Wiselink today, a reputable supplier and distributor of quality electronic components. By offering a diverse range of authentic components, such as Mill-Max sockets and spring loaded connectors, we are dedicated to supporting you in developing great products that surpass customer expectations. Explore our website and find out how Wiselink can become your partner in procuring top-notch electronic components for your next technological breakthrough.