The Mechanics of Pogo Pins: How Does a Pogo Pin Work?

Previously, we covered an introduction to pogo pins, exploring their fundamental attributes and applications that make them a staple in various industries. In this article, we will unravel the mechanisms that govern the functionality of pogo pins.

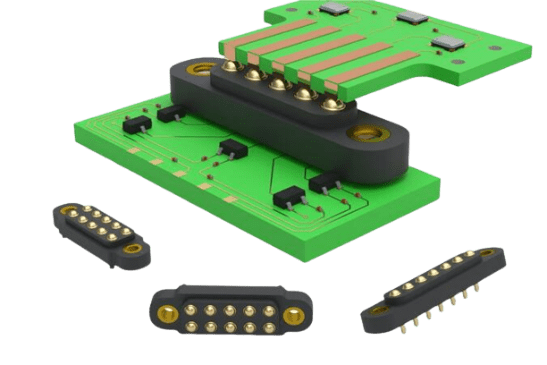

Construction of a Pogo Pin

A pogo pin typically consists of several key components:

- Housing: Serving as the external shell, the housing encapsulates and protects all internal components of the pogo pin. This structural element ensures mechanical resilience and stability in various applications.

- Spring Mechanism: The core mechanism of the pogo pin lies in its spring mechanism. Central to this mechanism is a coiled spring, made from a conductive material to facilitate electrical connectivity. This spring can undergo both compression and extension, providing the pogo pin with its distinctive functionality.

- Plunger: The plunger is the dynamic portion of the pogo pin, responsible for extending and retracting. It remains interconnected with the coiled spring and operates within the confines of the housing. The plunger’s movement is facilitated by the spring’s elasticity.

- Tip: At the end of the plunger is the tip. This tip constitutes the point of contact responsible for establishing an electrical connection with another surface or component. The tip’s design and material contribute to efficient and reliable electrical conductivity.

Working Principle of a Pogo Pin

The operational principle of a pogo pin involves a dynamic interplay between applied external forces and the inherent mechanical properties of its components. This process culminates in the storage and release of potential energy, facilitating its electrical connectivity. The sequence of events is as follows:

1. Initial State: In its resting state, the pogo pin assumes a configuration where the spring mechanism is in an extended position. This configuration positions the tip away from its intended contact point, ensuring no electrical connection is established.

2. External Force Application: Upon applying an external force to the tip of the pogo pin, this force is transmitted through the plunger. The plunger, in turn, compresses the coiled spring residing within the pin’s housing. This forceful compression is possible due to the spring’s inherent flexibility and resilience.

3. Spring Compression: As the spring compresses, it accumulates potential energy within its coils. This energy is a result of the deformation of the spring from its original extended configuration. The spring’s conductive nature ensures electrical continuity during this compression phase.

4. Potential Energy Storage: The compressed spring stores this potential energy within its coiled structure. This energy is ready to be harnessed for the subsequent stages of the pogo pin’s operation.

5. Release and Retraction: When the external force is either diminished or eliminated, the spring within the pogo pin resumes its relaxed state. Consequently, the plunger retracts, causing the tip of the pin to disengage from the targeted surface. This orchestrated disconnection is vital, as it averts the risk of accidental short circuits and preserves the integrity of the overall connection interface.

Applications of Pogo Pins

Pogo pins are versatile and efficient components that find applications across various industries due to their unique capabilities. These applications include:

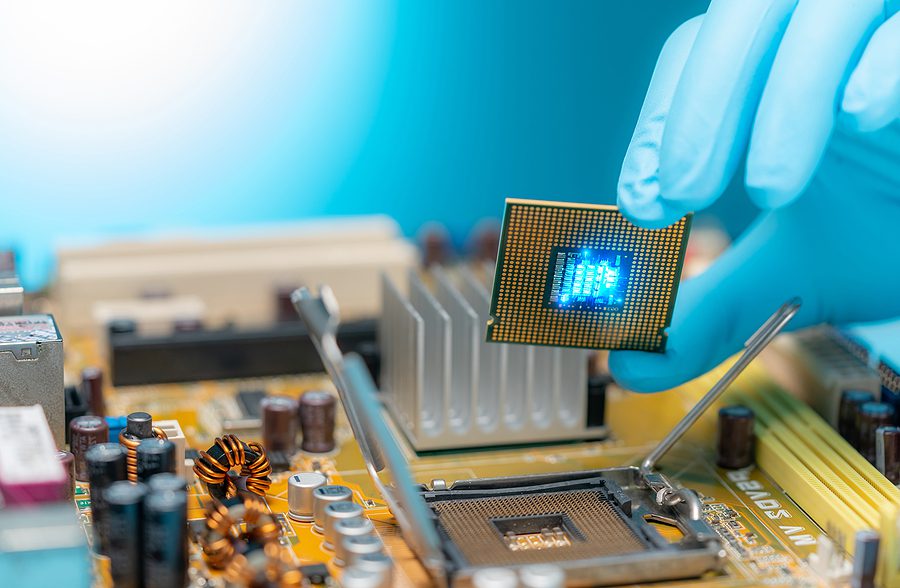

- Test Fixtures in Electronics Manufacturing: Pogo pins play a crucial role in electronics manufacturing by being an integral part of test fixtures. These pins facilitate quick and dependable connections when testing different aspects of printed circuit boards (PCBs). This ensures effective quality control and a thorough assessment of PCB functionality before finalising the production process.

- Docking Stations for Devices: Pogo pins are essential in docking stations designed for devices like smartphones and laptops. These pins serve as connectors that enable seamless power and data transfer between the docking station and the device itself. This streamlined connection process ensures efficient charging and smooth data synchronisation between the two entities.

- Medical Device Applications: Pogo pins find valuable use in the medical field, particularly in medical devices where consistent and reliable connections are paramount. Such devices include patient monitoring equipment and diagnostic tools. The reliable connections facilitated by pogo pins contribute to accurate data transmission and overall device performance.

- Automotive Industry Uses: Pogo pins serve various functions within the automotive sector, ranging from diagnostics in service centres to programming electronic control units (ECUs) during vehicle assembly. These pins enable efficient and accurate connections, ensuring that tasks such as vehicle diagnostics and ECU programming are carried out with precision and reliability.

Conclusion

Pogo pins might seem small and unassuming, but their impact on modern electronics and various industries is significant. These cleverly designed components ensure reliable connections, efficient signal transmission, and the seamless functioning of devices we rely on daily.

Wiselink is your premier electronic component store in Singapore, offering a diverse range of top-quality pogo pins and much more. Experience the convenience of a one-stop shop for all your electronics needs. Shop our extensive catalogue today and experience the next level of reliability and performance.